Indian Researchers Innovate Method to Eliminate Toxic Chromium from Wastewater Using Sunlight

Dr. Bhanu Prakash and Team at INST Utilize Sunlight and Microfluidics for Effective Chromium Removal from Wastewater

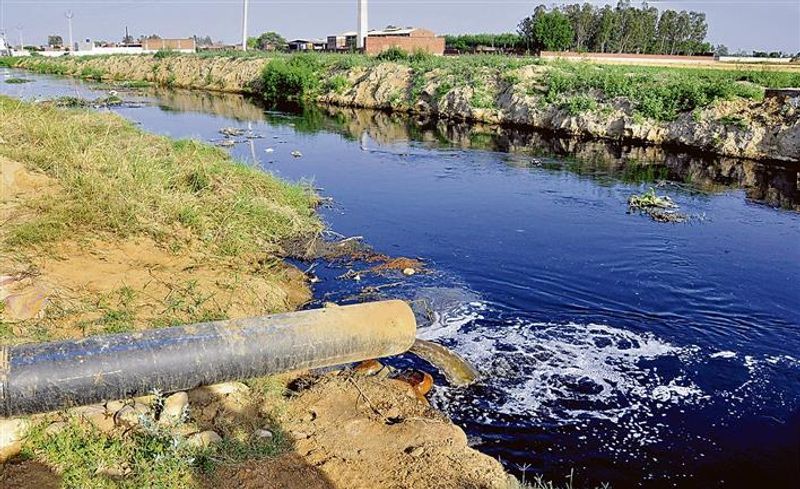

Researchers at the Institute of Nano Science and Technology (INST) in Mohali, India, have made a significant advancement in addressing the challenge of chromium contamination in wastewater. Led by Dr. Bhanu Prakash, the team has developed an innovative technique that utilizes sunlight as a catalyst, combined with microfluidic technology, to convert toxic hexavalent chromium (Cr(VI)) into the less harmful trivalent chromium (Cr(III)). This breakthrough could have far-reaching implications for industries such as leather tanning and electroplating, which are known for discharging high levels of chromium into the environment.

The World Health Organisation (WHO) has established stringent standards for chromium levels in drinking water, setting limits at 0.05 mg/L for hexavalent chromium and 5 mg/L for trivalent chromium. The high toxicity of hexavalent chromium makes its removal from wastewater critical to public health and environmental safety. Traditional methods for eliminating chromium from water—such as ion exchange, adsorption, and chemical reduction—are often expensive and may not achieve the desired efficiency. This underscores the urgent need for more effective and cost-efficient solutions.

The new method introduced by Dr. Prakash’s team employs a continuous flow photoreduction process that uses titanium dioxide (TiO2) nanoparticles along with sunlight. This innovative approach takes advantage of the photocatalytic properties of TiO2, which activates under UV light to facilitate the conversion of Cr(VI) to Cr(III). The researchers have further validated their method using a smartphone-based colourimetric technique to monitor the reduction of chromium in wastewater, making the process not only efficient but also accessible for real-time analysis.

The integration of microfluidic technology plays a crucial role in enhancing the performance of this new technique. By allowing precise control over flow rates and reactor dimensions, microfluidics optimizes the conditions for chromium reduction, ensuring that the chemical reactions occur efficiently. This level of control enables the researchers to fine-tune the process, potentially leading to higher rates of chromium conversion and lower overall costs compared to traditional methods.

This research has significant implications for industries that regularly deal with chromium discharge. The leather tanning industry, for example, often faces scrutiny due to its environmental impact, particularly regarding wastewater management. By implementing this new technique, industries could not only comply with stringent environmental regulations but also reduce their ecological footprint. Furthermore, the method’s reliance on sunlight makes it a sustainable alternative, utilizing renewable energy for a crucial environmental process.

Overall, the work done by Dr. Bhanu Prakash and his team at INST represents a promising step forward in the quest to mitigate chromium contamination in wastewater. By combining innovative materials and technologies, they have developed a method that not only addresses an urgent environmental challenge but also offers a sustainable approach to wastewater treatment. As this research progresses, it could pave the way for widespread adoption in various industries, contributing to cleaner water systems and a healthier environment.