A team of engineers has pioneered two new methods for shaping carbon electrodes derived from bread, offering promising potential for more sustainable electrode production. The innovative techniques are a continuation of prior research, aiming to address the challenges of producing carbon electrodes from food waste, specifically stale bread. By repurposing bread—an often discarded item—the researchers have found a way to convert it into a valuable material that can be used in various applications, such as desalination systems. This breakthrough process involves heating stale bread in an oxygen-free environment, transforming it into carbon, a substance commonly used for manufacturing electrodes. The team’s ultimate goal is to refine these techniques for large-scale production, providing an environmentally friendly alternative to traditional carbon electrode materials.

The research, published in Royal Society Open Science, was carried out by engineers David Bujdos, Zachary Kuzel, and Adam Wood from Saint Vincent College and the University of Pittsburgh. Building upon earlier work by Adam Wood, which established that stale bread contains sufficient carbon to be used in electrode production, the team has developed new methods to refine the shaping process. Wood’s initial work demonstrated that stale bread, once heated and transformed, could serve as a viable material for carbon electrodes. This discovery opened up new possibilities for using food waste in high-tech applications, a concept that has captured the attention of sustainability advocates.

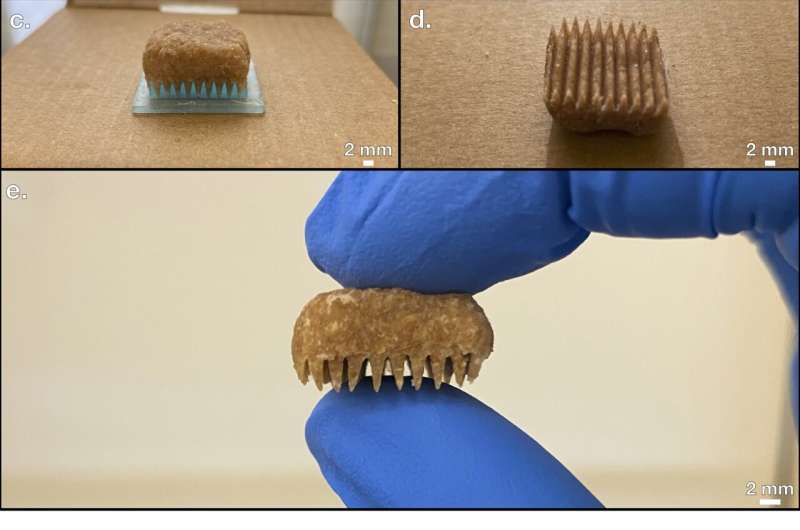

The newly developed methods involve two distinct approaches for molding carbon electrodes into precise, sturdy shapes. One technique uses 3D-printed molds to compress the bread before it undergoes the heating process. This compression step ensures that the bread retains its shape and forms a consistent structure suitable for electrode production. In one demonstration, a zigzag mold was employed to showcase the potential for creating electrodes with complex shapes. This ability to control the final shape of the electrodes is a significant advancement, as it allows for more targeted applications in industries that require specific electrode configurations.

These new shaping techniques represent a significant step forward in making the production of carbon electrodes more sustainable. By utilizing a commonly wasted food source like stale bread, the engineers have found a way to reduce waste while simultaneously addressing the growing demand for eco-friendly alternatives in industrial manufacturing. The team’s work not only holds promise for the future of electrode production but also contributes to the broader movement towards sustainability in science and technology. If successful at scale, this method could revolutionize how electrodes are made, offering a green solution to a critical component in various industrial and environmental technologies.